Anoxic Tank Design

As a renowned pump manufacturer Grundfos delivers efficient reliable and sustainable solutions all. The chemical and petrochemical industries are described in The Petroleum Chemicals Industry Goldstein and Waddams 1967 The Petrochemical Industry Hahn and Williams 1970.

Why Is Sludge Blending Important Anoxic Aerobic Digestion

TABLE 1 KEY DESIGN PARAMETERS FOR A CONVENTIONAL LOAD Municipal Industrial Food to Mass FM 015 - 04day 015 - 06day.

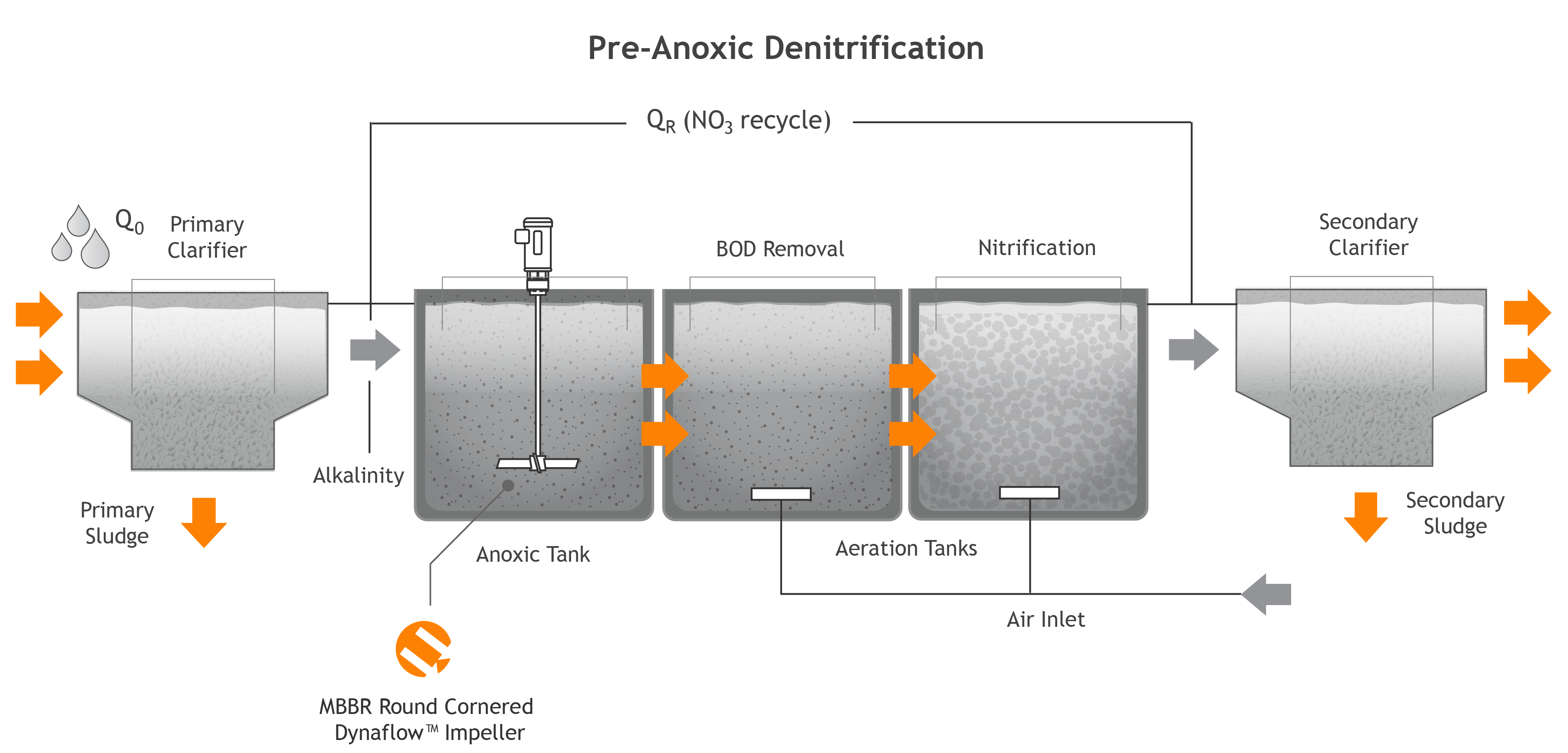

. Oxygen Production for both Oxycline and in the anoxic bottom Layers of Lakes via Catalytic Reaction Oxygen Production for Aquaculture Pond Health Treatment of any Waste Water with Advanced Oxidation Process Sewage Reuse for Irrigation after RedOxy-3C Treatment Sulfur Oxidation Ferrous Oxidation a simple and low-cost Oxydes Technology. The first process in the treatment train is a pre-anoxic basin where influent wastewater return sludge from the clarifier and nitrate-rich mixed liquor. Moving Bed Biofilm Reactor MBBR The Ecologix MBBR is a highly effective biological treatment process based on a combination of conventional activated sludge process and biofilm media.

Chemical addition should be evaluated for two. For phthalate mixture biodegradation by Gordonia sp. In a continuous stirred tank bioreactor CSTB initial concentrations of phthalates were chosen based on the degradation results of the shake flask study.

Chemical Treatment Design Components Less complicated than biological approaches the chemical treatment design approach consists of a mass balance between chemical addition the stoichiometry of the chemical added and phosphorus removed and the phosphorus concentration after chemical addition. RVE provided design engineering services as well as material shop drawing reviews. Based on these parameters and other site specific parameters such as temperature key design parameters are selected for the system.

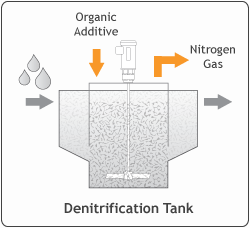

Necessary for most surface waters especially at intake. Denitrification being an anoxic process is conducted in a separate bioreactor. The Modified Ludzack-Ettinger process is designed to use nitrate produced by the aeration zone as an oxygen source for facultative bacteria in the breakdown of raw wastewater in the anoxic basin.

The full range supplier of pumps and pump solutions. Conventional drinking water treatment processes Aeration. Nitrification is accomplished in the aerobic tank itself simultaneously with carbon removal during which the dissolved ammonia in wastewater is converted to nitrates.

Mortality can result from prolonged exposure to such lethal concentrations. With such tight buffer zones space was at a premium. An example of these parameters for a wastewater system loading is listed in Table 1.

During high water periods water which spills over the crest of the dam can become over-saturated with atmospheric gases oxygen and nitrogen to a level which can be lethal for fish. In Lees Loss Prevention in the Process Industries Third Edition 2005. Necessary for GWs that are anoxic Oxidation of reduced forms of FeII to FeIII and MnII to MnIV For As-contaminated water it can result in substantial removal of As too Types of aerators.

A critical concern was the location of the proposed third SBR tank. Moreover DO measurement was carried out in the anoxic tank with of 4. In addition height was a concern due to potential interference with the flight paths of wetland birds including bald eagles.

Release of anoxic water from the hypolimnion can cause fish mortality below dams Bradka and Rehackova 1964. Past reports had identified one of the. During denitrification the nitrates formed during nitrification are reduced to nitrogen gas.

The microorganisms consume organic material. As the number of experimental runs specified by the factorial design was high 16. The MBBR process utilizes floating High Capacity MicroOrganism BioChips media within the aeration and anoxic tanks.

Cascade fountain tray diffusers Screening. Continuous stirred tank bioreactor CSTB experiments.

Schematic Diagram Of Anaerobic Anoxic Oxic Aao Activated Sludge System Download Scientific Diagram

Plutocalc Designer Handbook Mbr For Bod And No3 Removal

Anoxic Process Type Of Anoxic Process Wastewater Treatment Youtube

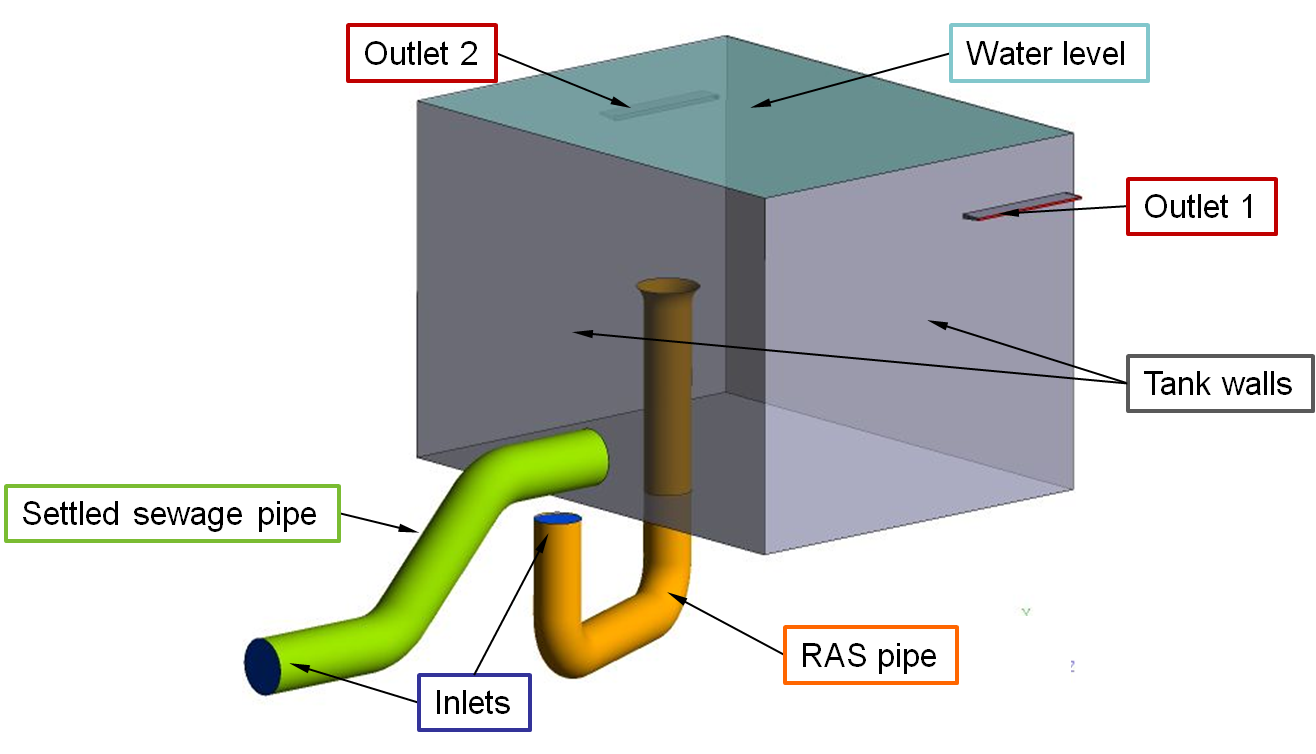

Optimising Solids Distribution And Mixing In An Anoxic Selector Tank Mmi Joins Thornton Tomasetti

Ebpr A2o Design Calculations Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel

A Anoxic Tank B Oxic Tank C Effluent Basin D Coagulant Basin Download Scientific Diagram

Why Is Mixing Needed In Anoxic And Anaerobic Zones Xylem Us

Anoxic And Aerobic Values For The Yield Coefficient Of The Heterotrophic Biomass Determination At Full Scale Plants And Consequences On Simulations

0 Response to "Anoxic Tank Design"

Post a Comment